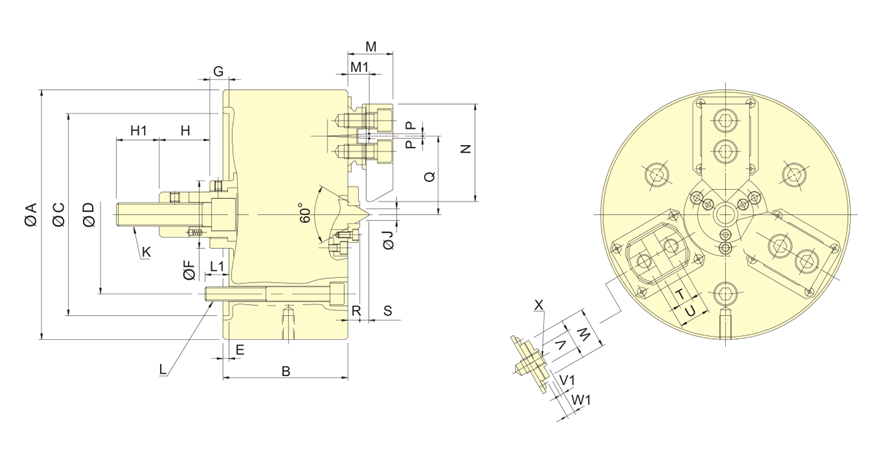

SWING COMPENSATION TYPE 3 JAW CHUCK

Click on product image magnification

Online inquiryBrand:NTH

The compensation for eccentric workpiece is 2mm, positioned by the core center,3 jaw clamp the workpiece by swing way.

| Spec/Model |

Plunger stroke mm |

Jaw stroke Dia. mm |

Max chucking Dia. mm |

Min chucking Dia. mm |

Max.D.B.Pull kgf |

|---|---|---|---|---|---|

| FR-08 | 20 | 8 | 65 | 18 | 19.6(2000) |

| FR-10 | 25 | 10 | 90 | 22 | 29.4(3000) |

| Spec/Model |

Max clamping force kgf |

Max RPM |

Inertia moment kg*m2 |

Weight kg |

Matched cylinders |

Compensation mm |

|---|---|---|---|---|---|---|

| FR-08 | 53.0(5404) | 2800 | 0.15 | 27 | SNK-100 | 2 |

| FR-10 | 67.7(6901) | 2500 | 0.38 | 45 | SNK-125 | 2 |

| Spec/Model | A | B | C(H6) | D | E | F | G max | G min | H | H1 | J | K | L | L1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FR-08 | 210 | 105 | 170 | 133.4 | 5 | 57 | 26 | 6 | 42.5 | 36 | 10.4 | M20×2.5 | 3~M12 | 20 |

| FR-10 | 254 | 115 | 220 | 171.4 | 5.5 | 64 | 36.5 | 11.5 | 25 | 39 | 15 | M20×2.5 | 3~M16 | 22.5 |

| Spec/Model | M | M1 | N | P | Q max | Q min | R | S | T(H7) | U | V | V1 | W | W1 | X |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FR-08 | 38 | 18 | 82 | 2 | 68 | 64 | 10 | 7.7 | 12 | 26 | 16 | 3 | 35 | 7 | m12 |

| FR-10 | 40 | 19 | 102 | 2.6 | 82 | 78 | 10 | 11.3 | 15 | 32 | 18 | 3 | 40 | 7 | m14 |

Subject to technology changes without prior information

Non-standard requirements can be made

Exhibition:MANUFACTURING INDONESIA 2025 Date:03. - 06. December 2025 Time:10:00 am. – 06:00 pm. Add: Balai Sidang Jakarta Convention Center,Jakarta,Indonesia Booth:A-150

Learn moreExhibition:METALEX 2025 Date:From 19 to 22 November, 2025 Time:10:00 am. – 06:00 pm. Add: BITEC International Trade & Exhibition Centre,Bangkok, Thailand Booth:H101-BD01

Learn moreExhibition:MSV 2025 International Engineering Fair Date: Tuesday, October 7, 2025 - Friday, October 10, 2025 Add: Brno Exhibition Centre, Brno, Czech Republic Booth:P-115

Learn more