Brand:NTH

To prevent deformation of workpiece as gripping the end surface, suitable for thin workpiece process.

The compensating mechanism of gripping that can clamp irregular surface workpieces.

It can go with the check device to inspect the clamping status.

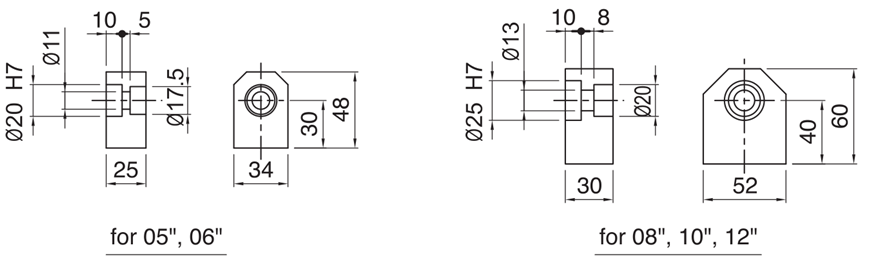

Size unit: mm

|

Spec / Model

|

Plunger stroke

mm

|

Jaw stroke Dia.

mm

|

Max chucking Dia.

mm

|

Min chucking Dia.

mm

|

Max.D.B.Pull

KN(kgf)

|

|

3F-05

|

12

|

8

|

53

|

25

|

7.5(765)

|

|

3F-06

|

12

|

8

|

79

|

55

|

9.0(918)

|

|

3F-08

|

12

|

8

|

106

|

75

|

18.0(1835)

|

|

3F-10

|

12

|

8

|

150

|

119

|

18.0(1835)

|

|

3F-12

|

12

|

8

|

200

|

169

|

18.0(1835)

|

|

Spec

/ Model

|

Max clamping force

KN(kgf)

|

Max RPM

|

Inertia

kg*m2

|

Weight

kg

|

Matched cylinders

|

Max Pressure

Mpa(kgf)

|

|

3F-05

|

6.0(612)

|

4000

|

0.02

|

11

|

S-100R/SNK-100

|

1.0(10)

|

|

3F-06

|

7.5(765)

|

4000

|

0.04

|

12

|

S-100R/SNK-100

|

1.2(12)

|

|

3F-08

|

16.5(1680)

|

3500

|

0.13

|

23

|

S-100R/SNK-100

|

2.5(25)

|

|

3F-10

|

16.5(1680)

|

3500

|

0.3

|

33

|

S-100R/SNK-100

|

2.5(25)

|

|

3F-12

|

16.5(1680)

|

3000

|

0.56

|

44

|

S-100R/SNK-100

|

2.5(25)

|

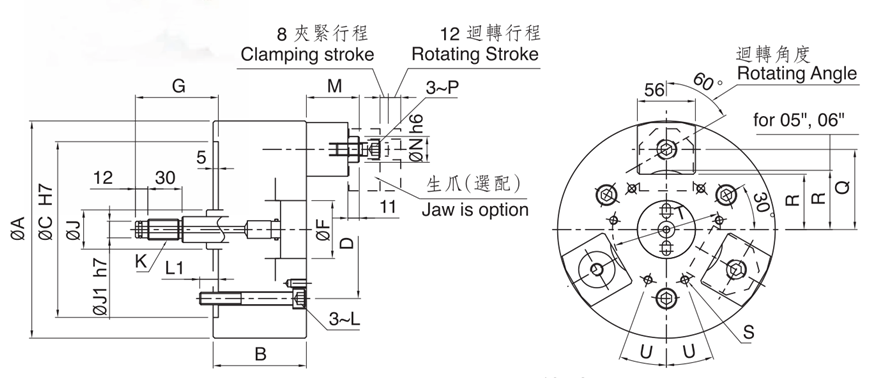

Spec

/ Model

|

A

|

B

|

C

|

D

|

F

|

G Max

|

G Min

|

J

|

J1

|

K

|

|

3F-05

|

135

|

86

|

110

|

82.6

|

40

|

75

|

55

|

25

|

10

|

M12×1.75

|

|

3F-06

|

165

|

86

|

140

|

104.8

|

45

|

75

|

55

|

28

|

14

|

M16×2

|

|

3F-08

|

210

|

90

|

170

|

133.4

|

56

|

80

|

60

|

38

|

16

|

M20×2.5

|

|

3F-10

|

254

|

95

|

220

|

171.4

|

56

|

75

|

55

|

38

|

16

|

M20×2.5

|

|

3F-12

|

304

|

95

|

220

|

171.4

|

56

|

75

|

55

|

38

|

16

|

M20×2.5

|

Spec /

Model

|

L

|

L1

|

M Max

|

M Min

|

N

|

P

|

Q

|

R

|

S

|

T

|

U

|

|

3F-05

|

M10

|

15

|

56

|

36

|

20

|

M10

|

42.5

|

27

|

3-M6

|

50

|

-

|

|

3F-06

|

M10

|

15

|

56

|

36

|

20

|

M10

|

57.5

|

40

|

3-M8

|

64

|

20°

|

|

3F-08

|

M12

|

18

|

71

|

51

|

25

|

M12

|

77.5

|

53.5

|

6-M8

|

104

|

20°

|

|

3F-10

|

M16

|

24

|

71

|

51

|

25

|

M12

|

99.5

|

75.5

|

6-M8

|

140

|

20°

|

|

3F-12

|

M16

|

24

|

71

|

51

|

25

|

M12

|

124.5

|

100.5

|

6-M8

|

190

|

20°

|

Subject to technology changes without prior information

Non-standard requirements can be made