JAM/JHM SPINDLE COLLET CHUCK

Click on product image magnification

Online inquiry品牌/Brand:NTH

专利空油压主轴筒夹夹座

整合筒夹夹头、回转主轴与驱动系统An integration of a rotary spindle, a power collet chuck,and an actuator.Specially designed for double-ended machining: saving setup,loading, and machining time.Accelerating the designing and building cycle of a new special purpose machine.

Compact size.

High clamping force. High rigidity.

产品介绍

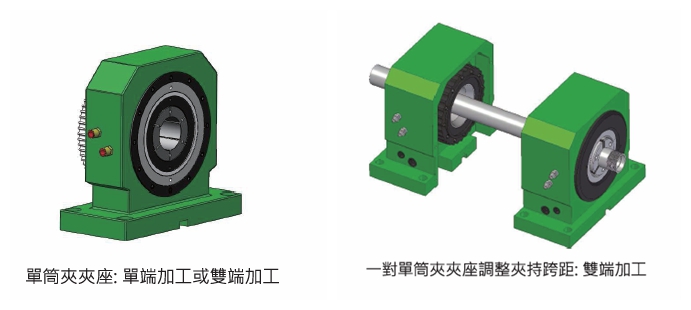

JAM/JHM空油压主轴筒夹夹座是专为双端型/对构型工件加工所设计的专用主轴夹座。主轴夹座整合筒夹夹头与回转主轴,体积小,外形薄,方便设计自动送料系统。工件在一次的夹持动作内可以完成工件双端同时加工,大幅提高工作效率并减少加工机台的设备成本。应用主轴筒夹夹座设计各式加工专用机械。可以缩短工程人员的开发时程与组立时程。帮助产品更快的投入市场。在应用上,针对短型零件,客户可以应用一对主轴筒夹夹座进行单端加工或双端同时加工。目前,双向主轴夹座已经广泛的应用于多种零件的加工专用机械,包含:自行车零件、汽车零件、机车零件、军用零件、运动器材零件等。

NTH JAM/JHM Spindle Collet Chuck is specially designed to provide the users with an all-in-one solution to build their special purpose machines. A traditional workholding system consists of a rotary spindle, a power chuck, and a actuator. JAM/JHM Spindle Collet Chuck combines these three elements in one, making machine builders very easy to design and to build a new special purpose machine. Since the gripping length of JAM/JHM Chucks are longer than regular collet chucks, JAM/JHM is mostly applied to grip double-ended work parts like hubs of bicycle wheels or piston rods of automobiles.

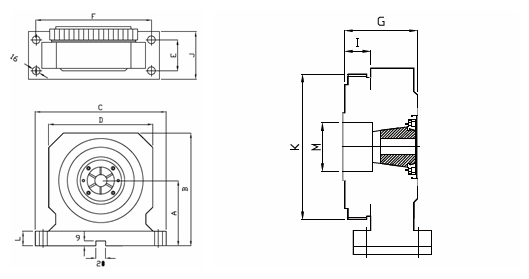

| 型号/Model |

JAM-25 Push forward (滑套前推夹紧) |

JAM-72 Push forward (滑套前推夹紧) |

JHM-65(Pull back) (滑套后推夹紧) |

|---|---|---|---|

|

A(Center H) |

135(5.31〞) | 145(5.71〞) | 145(5.71〞) |

| B | 232(9.13〞) | 265(10.43〞) | 255(10.04〞) |

| C | 270(10.63〞) | 288(11.34〞) | 260(10.24〞) |

| D | 210(8.27〞) | 236(9.29〞) | 220(8.66〞) |

| E | 64(2.52〞) | 105(4.13〞) | 92(3.62〞) |

| F | 238(9.37〞) | 256(10.08〞) | 228(8.98〞) |

| G | 92(3.62〞) | 111(4.37〞) | 106(4.17〞) |

| I(Pulley W) | 27(1.06〞) | 28.5(1.12〞) | 27(1.06〞) |

| J | 98(3.86〞) | 135(5.31〞) | 124(4.88〞) |

| K | 182(7.17〞) | 202(7.95〞) | 177(6.97〞) |

| L | 30(1.18〞) | 34(1.34〞) | 30(1.18〞) |

| M | 57(2.24〞) | 83(3.28〞) | 87(3.43〞) |

| 工作筒夹 collet | ER-40筒夹 | JR-72筒夹 | JR-65筒夹 |

| 驱动 Power | 气压Air | 气压Air | 油压 Hydraulic |

| 工作压力 Working Pressure | 2-8kg/cm² (29-114psi) | 2-8kg/cm² (29-114psi) | 10-20kg/cm² (143-286psi) |

| 最高转速 Max RPM | 1800 | 2000 | 2000 |

| 皮带轮规格 Pulley Type | 8M-72齿 | 8M-80齿 | 8M-70齿 |

| 夹持范围 Clamping Range | 4-26mm (0.16〞-1.02〞) | 25-70mm (0.98〞-2.76〞) | 25-65mm(0.98〞-2.56〞) |

| 活塞面积 Piston Area | 145cm²(22.5in²) | 177cm²(27.4in²) | 44cm²(6.82in²) |

| 夹持力 Clamping Force |

4070kgf@7kg/cm² (8954lbf@100psi) |

4070kgf@7kg/cm² (8954lbf@101psi) |

3080kgf@20kg/cm² (6775lbf@286psi) |

| 产品净重 N . W | 22.5kgs(49.5lbs) | 39.0kgs(85.8lbs) | 29.0kgs(63.8lbs) |

JAM/JHM 空油压主轴夹座应用案例

JAM/JHM AIR/HYDRAULIC POWER SPINDLE COLLET CHUCK APPLICATION

针对追求高生产效率的加工专用机械,提出了全新的夹具设计观念。传统的自动化工件夹持系统是由一系列的标准化组件所组成,包含了回转主轴、动力夹头、及液气压驱动系统。JAW/JHM空油压主轴夹座将三者整合为一。大幅提升加工专用机械的设计弹性生产效率。应用主轴夹座,专用机械能大量缩短工件送料行程与装夹的时间。此外,由于主轴夹座的外型短薄,短型工件能在一次的装夹作业完成工件双端同时加工,而长型工件能以一对单筒夹主轴夹座在一次的装夹完成工件双端同时加工。目前设计有一系列的筒夹主轴夹座,能适应多种加工件。

保留技术更改的权利,恕不另行通知 Subject to technology changes without prior information

非标需求可定做 Non-standard requirements can be made

Exhibition:MANUFACTURING INDONESIA 2025 Date:03. - 06. December 2025 Time:10:00 am. – 06:00 pm. Add: Balai Sidang Jakarta Convention Center,Jakarta,Indonesia Booth:A-150

Learn moreExhibition:METALEX 2025 Date:From 19 to 22 November, 2025 Time:10:00 am. – 06:00 pm. Add: BITEC International Trade & Exhibition Centre,Bangkok, Thailand Booth:H101-BD01

Learn moreExhibition:MSV 2025 International Engineering Fair Date: Tuesday, October 7, 2025 - Friday, October 10, 2025 Add: Brno Exhibition Centre, Brno, Czech Republic Booth:P-115

Learn more